QUV Yellowing Study

Two major misleading statements are being made to residential garage homeowners.

One is that epoxy and polyurea pigmented coatings do not yellow when exposed to UV rays of sunlight. The other is a clear polyaspartic topcoat will filter or block the UV rays and prevent yellowing.

Yes, epoxy and polyurea pigmented primer coatings do yellow from UV rays of sunlight. They yellow, fade and oxidize leading to micro cracking and weakening their adhesion to concrete.

No, clear polyaspartic topcoats do not block or filter UV rays of sunlight. They will pass through and attack the epoxy and polyurea resin binders of the coatings.

“In QUV testing FLEXMAR NextGen polyaspartic outperforms polyurea and epoxy.”

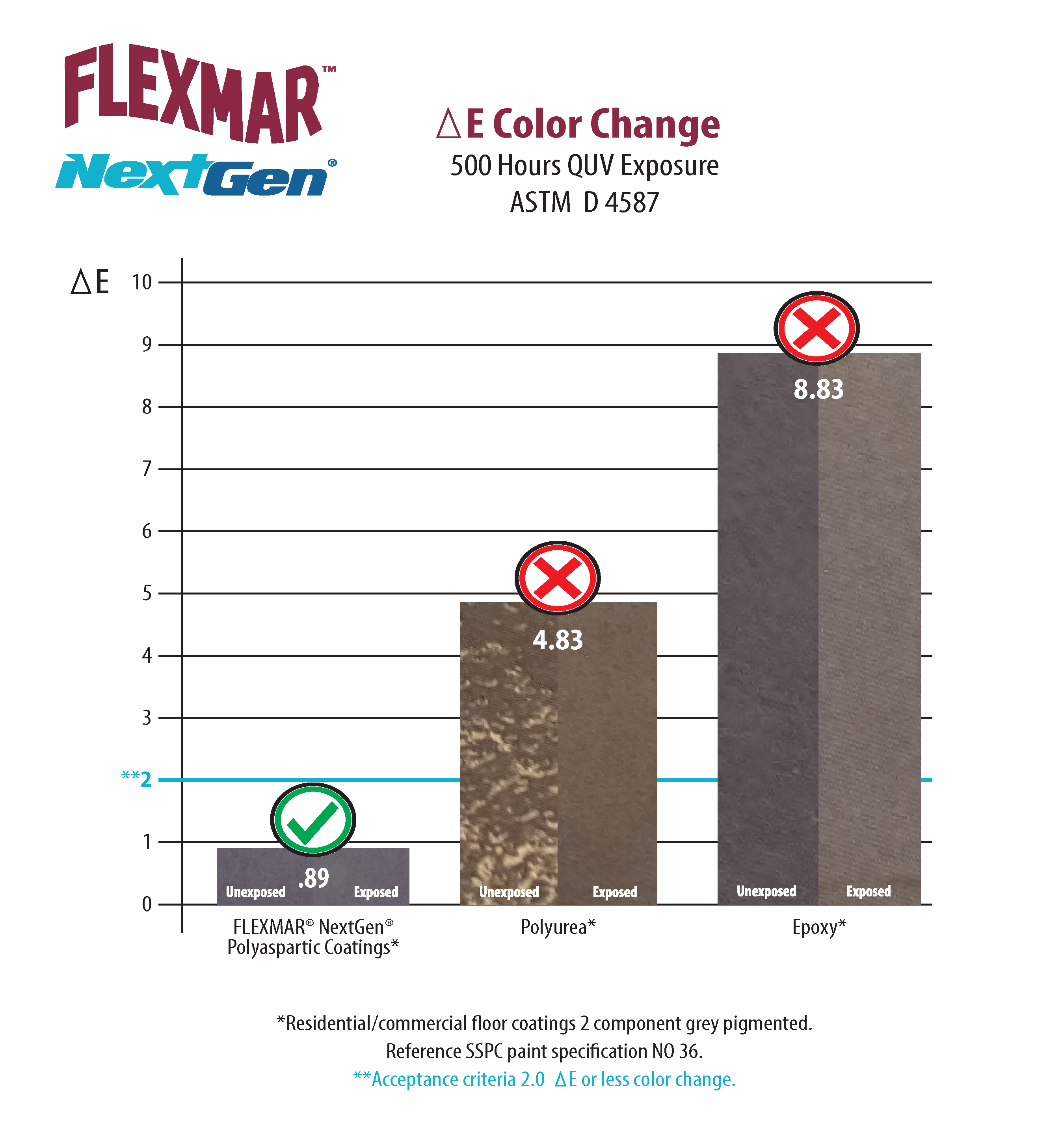

Today we want to clarify much confusion in the market place about UV light rays and their effects on ambering and yellowing of concrete floor coatings. We will show test results in a QUV accelerated weathering cabinet ( ASTM D 4587 ) that compares some industry names in polyurea and epoxy concrete floor coatings to a FLEXMAR polyaspartic. These self-prime color coats were pigmented light gray.

Many dealer -applicators claim their polyurea or epoxy coatings do not amber or yellow due to ultra violet light rays from the sun. This is contradictory to known technology so the purpose of this test is to demonstrate this fact. The chemistry of epoxy and polyurea coatings are aromatic in chemical composition and therefore are prone to ambering and yellowing from UV sunlight. The chemistry of polyaspartic coatings is aliphatic in chemical composition and is not prone to ambering and yellowing from UV sunlight.

These applicators through their coating suppliers, either brand names or private labels, promote 10 to 15 year warranties for residential garage floors against discoloration from UV exposure. But usually buried in the warranty is a disclaimer that it does not cover changes or oxidation of the coating as a result of normal weathering or atmospheric conditions. Oxidation is the result of UV and atmospheric conditions causing fading and micro cracking that weakens adhesion of the coating to concrete.

Ambering, yellowing and discoloration are detrimental for a floor coating in applications involving a full broadcast of color flake because a certain amount of UV will pass through the flakes. This would be even more dramatic if the floor would be a solid color without color flakes. After time the color coat if not UV resistant will amber or yellow and in the time period of the warranty the floor will not look like it did originally. The main objective is to have the color look the same in 10 to 15 years as it does today.

For the test results to be meaningful length of exposure time in the QUV accelerated weather cabinet was 500 hours in order to correlate to the acceptance criteria Level I of SSPC: Paint specification #36. The Society of Protective Coatings. The “ noticeable change” in color is defined as greater than 2.0 delta E.

The chart below clearly shows the exposure panels both before and after 500 hours exposure. The FLEXMAR gray polyaspartic had a delta E color change of .89 compared to a delta E color change of 4.83 for the gray polyurea and 8.83 for the gray epoxy. This is also visible as shown by the side-by-side panels where the polyuria and epoxy show visual ambering and yellowing. The FLEXMAR polyaspartic does not visually show ambering or yellowing, thus it’s .89 delta E color change.

CONCLUSION: The FLEXMAR polyaspartic would meet the Level I acceptance criteria of SSPC Paint Specification #36 while the polyurea and epoxy would fail.

This difference is dramatic and should cast doubt on claims that a polyurea or epoxy will not amber or yellow when exposed to UV sunlight. Some competitors disguise their claims of no ambering or yellowing by running similar QUV comparison testing but exposing their sample panels for less than 24 hours to show little or no ambering or yellowing. Beware of these misleading claims when discussing with uninformed sales persons.

Therefore, FLEXMAR who was the first company to introduce polyaspartic concrete floor coatings in year 2006 at the World of Concrete, has maintained that an all 100% polyaspartic floor coating system, both self-prime color coat and clear topcoat offers the best long-term life cycle when compared to one that has a polyurea or epoxy color coat primer and clear topcoat.

Ready for a FLEXMAR Floor?

Contact us today for more information about FLEXMAR products, available installation services through our applicator network, or if you need help choosing the right system for your floor.